The Resin Process

The process for producing resin must be fine-tuned according to some key parameters, such as material being processed (e.g. specific type of marble, granite, etc.), slab conditions (e.g. cracks and hole size, humidity) and desired finish (e.g. enhancement or preservation of natural color).

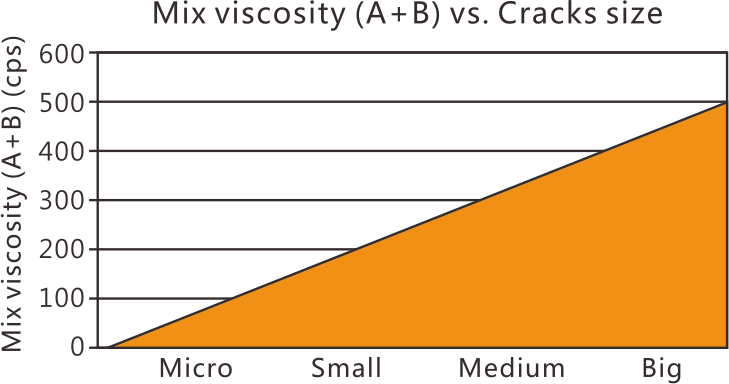

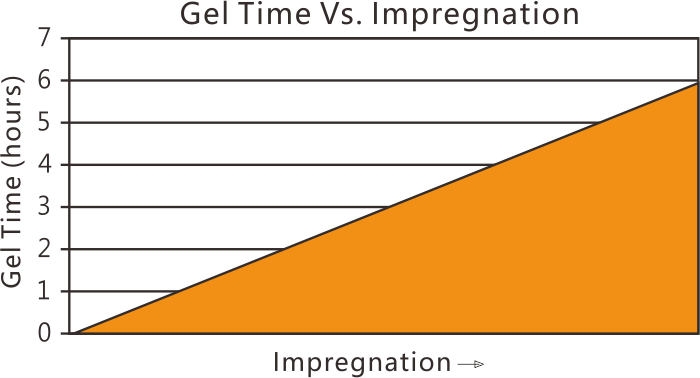

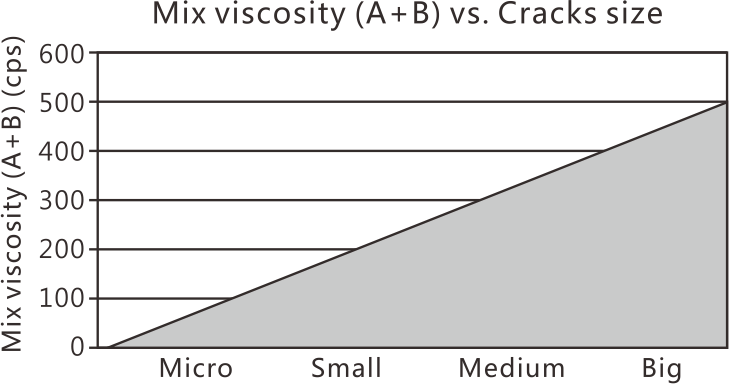

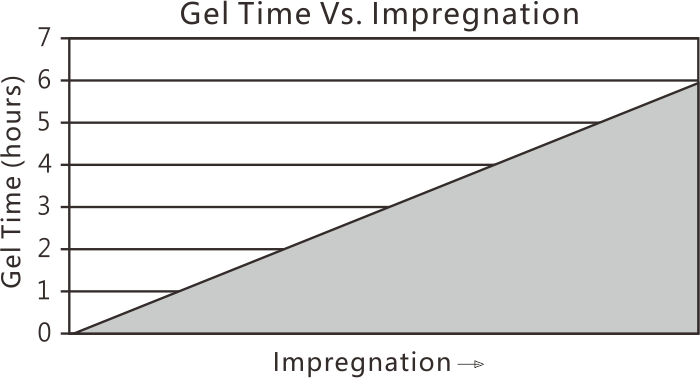

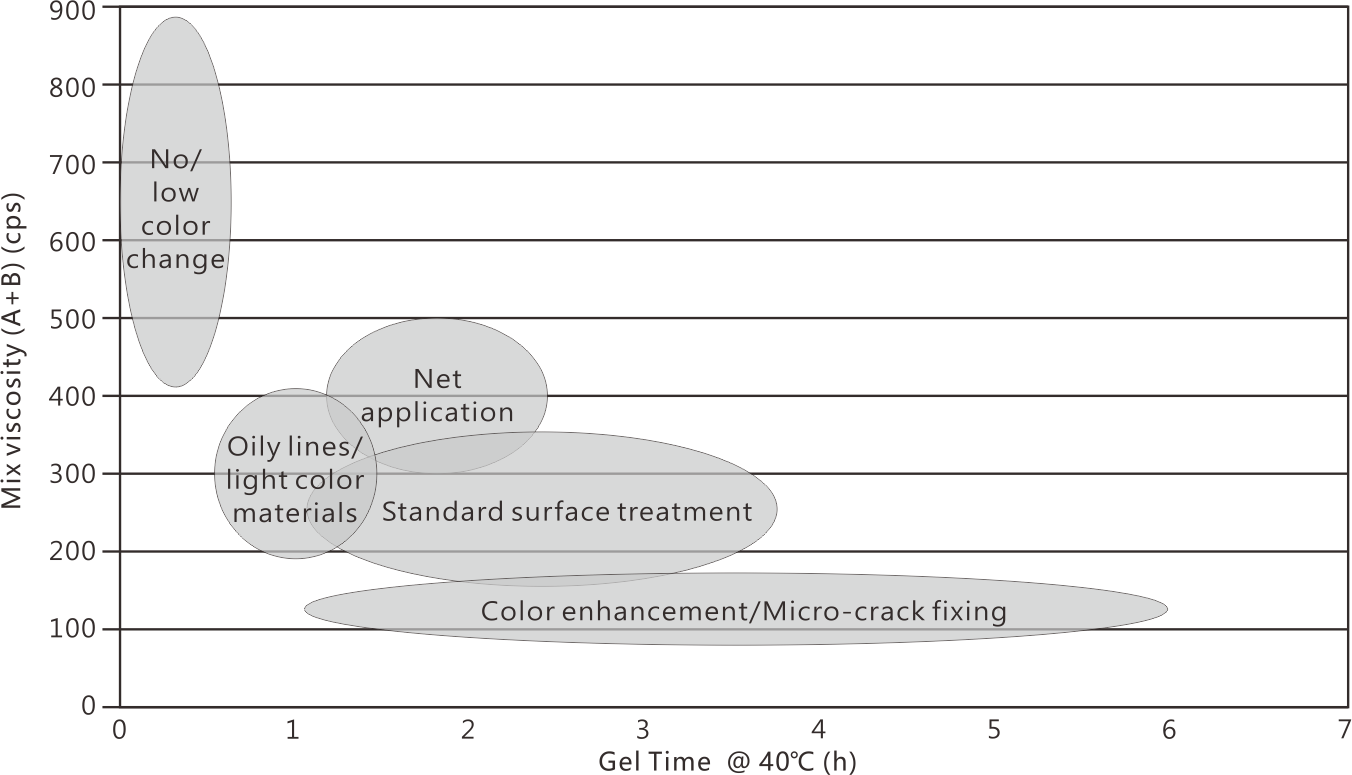

In general, the basic properties for the initial selection of the Epoxy System (A+B) are “Gel Time” and “Viscosity”. Then, the specific product must be chosen in order to optimize resin penetration in the cracks, mechanically strengthen the slab to the greatest possible level, and achieve the desired surface finishing and gloss. Particularly in the case of white and light colored materials, it is highly recommended to select products specifically designed to minimize UV-induced yellowing.

Epoxy consumption is greatly affected by material density and, in general, it can range from 50-100 g/m² (in the case of some very compact granites) to 300-350 g/m² (typical of many low density marbles and other materials). The specific resin amount also depends on many other variables, including the quality of the block, slab surface finishing, resin application technique, and the kind of resin itself.

(by Dr . Matteo Pietrini)

What is the best Resin Line?

One that satisfies customer's requirements.

A resin line is in fact a combination of standard automatic modules that can be assembled in such a way as to match the customer's process and space layout. If special modules need to be designed, VEEGOO can do it in order to optimize the customer's investment.

The basic criteria to design a resin line include:

- Back-netting: It can be performed in line or before sending the slab to the resin line.

- Slabs per hour.

- Space availability: Specific building constraints.

- Tuning of the resin line according to the customer's process and layout.

Once the above criteria are defined, the layout can be established.

Resin lines are a consolidated technology. Quality, productivity and reliability will come as direct consequences of the design principles, the quality of the components, the accuracy of the installation and the attention to detail.

Microwave Resin Line

Good dehydration effect, Save the drying and curing time, Climate-adaptive design, Enhanced space utilization, It is applicable to the glue - filling of luxury stones.

The resin line based on microwave drying ovens and catalytic ovens represents the third-generation product, offering a superior alternative to traditional resin lines with more extensive functionality. The system includes two types of ovens:

Both types of ovens feature modular structures, which can be easily integrated into existing traditional resin application lines to achieve cost savings. They can also serve as key components of new production lines.

Microwave drying oven

The microwave drying oven generates high temperatures through internal molecular vibration, causing water molecules to vaporize and escape, including the removal of structurally bound water molecules. This achieves rapid drying and is therefore used for immediate drying and dehydration.

Microwave Catalytic Oven

The microwave catalytic oven uses the high-frequency electromagnetic field of microwaves to induce polarization of resin molecules, enhancing the intermolecular forces and thus promoting the hardening reaction. It also reduces the activation energy of the hardening reaction, accelerating the cross-linking reaction of thermosetting materials such as epoxy resins. This results in shorter hardening times and improved mechanical properties of the hardening slabs.

Control

Resin processing of natural stones is a complex and stable technology.

By using correct design, proper materials, high quality components and by assuring an accurate installation they can be very reliable systems.

All Veegoo Resin Lines are automatic and managed by PLCs. This assure repeatability and makes operations more reliable and faster.